Julio, 2024

Imagine driving on a smooth, durable road made... out of recycled plastic bottles! Sounds futuristic, doesn't it?

Well, this is not an idea out of a science fiction movie, but an innovative reality that is transforming the world of road infrastructure. Dive into this journey through recycled asphalt and discover how the plastic bottles we throw away could be paving the way to a greener, more sustainable future.

A bit of history

The concept of using recycled plastic in road construction arose in response to two global problems: the management of plastic waste and the need for more durable and sustainable road infrastructure.

The first initiatives date back to the beginning of the 21st century, when researchers and companies started experimenting with the inclusion of recycled plastics in asphalt mixes.

In 2002, India became one of the pioneers in this field, developing a technique to mix plastic waste with hot asphalt, improving the durability of roads and reducing the accumulation of plastic waste.

What are Recycled Plastic Roads?

Roads made from recycled plastic integrate plastic waste into the asphalt mix used to pave roads.

This process involves shredding bottles and other discarded plastics, which are then melted and combined with hot asphalt. The proportion of plastic can vary, but generally constitutes between 5% and 10% of the total mix.

How are they made?

The process of creating roads from recycled plastic is fascinating and relatively simple:

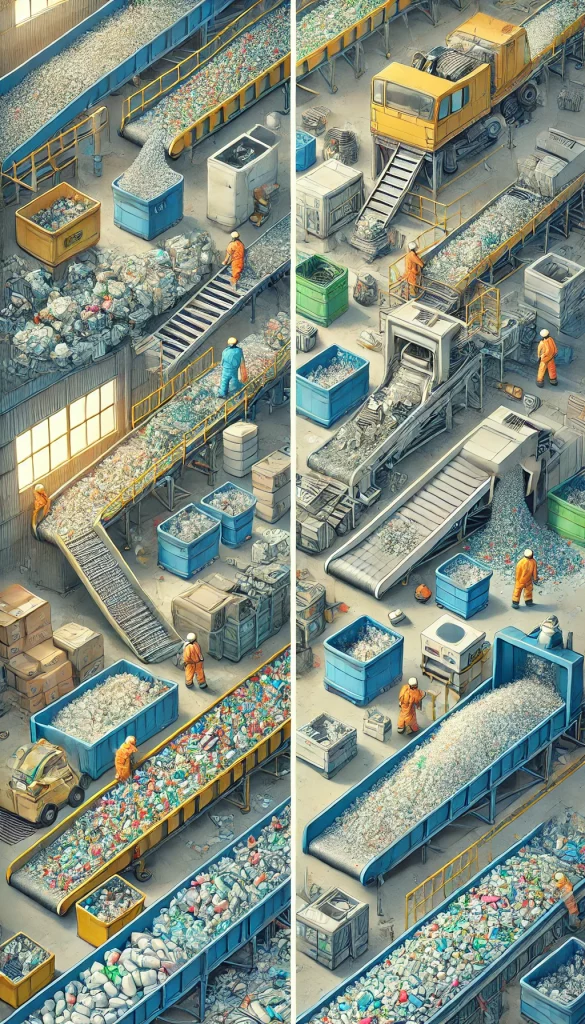

Collection and Classification: Plastic waste, such as bottles and packaging, is collected and then sorted according to type to ensure that only plastics suitable for the asphalt recycling process are used.

Cleaning and Shredding: The collected plastics are cleaned to remove any contaminants. They are then shredded into small fragments, preparing them to be mixed with asphalt.

Plastic Melting: The shredded plastic fragments are heated until they melt. This melted plastic is mixed with the hot asphalt, ensuring an even distribution of the plastic in the mix.

Asphalt Mix: The mixture of molten plastic and asphalt is continuously stirred to ensure that the plastic is fully and homogeneously incorporated into the asphalt.

Pavimentation: The asphalt and recycled plastic mixture is transported to the construction site. Here, it is spread and compacted on the road surface using conventional paving machinery, just as in the traditional asphalt paving process.

Cooling and Solidification: Finally, the newly paved road is allowed to cool and solidify, resulting in a durable and resistant surface made partly from recycled plastic.

Examples and Success Stories

– India: In several Indian cities, the implementation of recycled plastic roads has resulted in a marked improvement in durability and reduced maintenance costs.

- Scotland: MacRebur has developed a type of asphalt that includes recycled plastic, used in multiple infrastructure projects in the UK.

- The Netherlands: En Zwolle, se construyó la primera “Plasticroad” en 2018, una pista ciclista hecha completamente de plástico reciclado, demostrando el potencial de esta tecnología para aplicaciones más amplias.

Cost Comparison

Roads made from recycled plastic can be more expensive initially due to the need to collect and process the plastic. However, in the long run, these roads can be cheaper due to their longer durability and lower maintenance costs.

According to studies, the inclusion of recycled plastic can reduce maintenance costs by up to 30%, offsetting the higher initial expense.

Challenges & Solutions

- Plastic Quality: Not all types of plastic are suitable for recycling into asphalt. It is crucial to ensure that the plastic used is of high quality.

- Solution: Establish sorting and processing standards to ensure the quality of the recycled material.

- Asphalt Grip: The asphalt/plastic mixture must be homogeneous to ensure good adhesion and durability.

- Solution: Improve mixing techniques and use additives that improve the cohesion between asphalt and plastic.

- Initial Cost: Initial implementation can be more costly due to plastic collection and processing.

- Solution: Increase investments in recycling and paving technologies, and encourage government policies that subsidise sustainable projects.

Conclusions

Roads made from recycled plastic represent an innovative solution that combines waste management and the need for durable and sustainable infrastructure. Although they face challenges, the long-term environmental and economic benefits make this technology a promising option for the future of road infrastructure.